| |

|

|

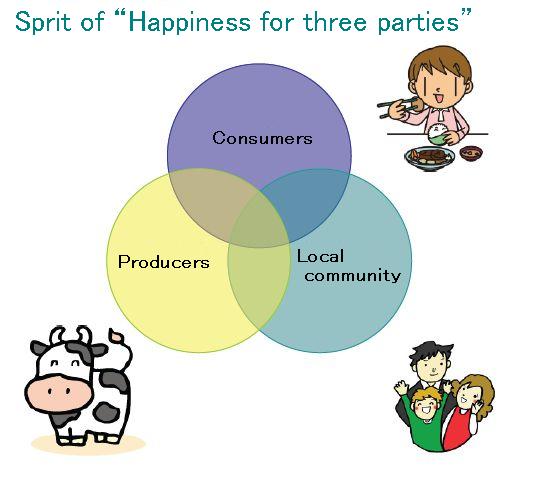

Challenge to large-scale livestock production by recycling |

resources and in coexistence with local community - based |

|

on the merchant spirit pursuing the common happiness for three |

|

parties (consumers - producers - local community) |

| |

| |

Kaneko Farm, Co., Ltd

|

| Shichinohe Town, Kamikita-gun, Aomori Prefecture |

|

|

|

| |

Reason for recommendation |

|

|

Kaneko Farm, Co., Ltd., (represented by Mr. Haruo Kaneko, CEO, 58 years old) is the largest cattle fattening farm of a grand scale in Aomori Prefecture, raising a total of about 8,300 heads of beef cattle consisting of breeds of Holstein, hybrids, and Japanese shorthorn, on the land of about 130 ha in Shichinohe Town in the livestock production zone of Prefecture. The annual amount of proceeds of the company reaches about 240 million yens.

Although the company has grown to the present scale after overcoming many difficulties, based on natural excellent gift for business operation and extraordinary efforts, the pursuit of profit is not the sole objective of company activities, but the principle lying at the base of business has been, consistently since its initiation, "Provision of animal products trusted by consumers by insisting on safety and reliability". Moreover, Mr. Kaneko, native to the neighboring village of Rokkasho, believes in the concept that business should be closely linked to local community, and as its practice, is devoting his efforts to promote such initiatives as: "respect for environmental conservation"; "challenge to livestock production based on the principle of resource recycling"; and "collaboration and integration with local community", all representing the attitude really deserving praise.

The factors that have been appreciated highly about this case are as follows:

|

|

|

(1) |

Insistence on safety and reliability

|

| |

|

In order to practice the principle of provision of animal products trusted by consumers by insisting on safety and reliability and prioritizing product safety over business efficiency, the farm fatten the cattle by feeding silage prepared from in-house grown maize of dent corn varieties, in-house blended formula feed without any additives of antibiotics, and roughages based on rice straw hay produced in the Prefecture. Having also introduced early the traceability system, the farm is presenting an exemplary case of attitude in the approach to securing product safety which should be emulated by others and appreciated highly.

Particularly with respect to the company’s own brand breed of Holstein, "Ken-Iku-Gyu" (health-growth-cattle) that has already become established as the signboard product of the company, the company sticks to the procedures of quality control beginning from the acquisition of feeder stock by introducing the cattle solely from reliable breeder farmers under contract, based on the concept that "Healthy and vigorous growth leads to safety and reliability".

The cattle of "Ken-Iku-Gyu", that are reared thus by insisting absolutely on product safety and reliability, can satisfy rigorous requirements imposed by large processing companies, being highly appreciated, and the latter are requesting the farm to augment further the number of heads to be traded. |

|

|

(2) |

Respect for environmental conservation |

| |

|

As a practice of business operation closely linked with local community, the company has so far been actively tackling the issue of environmental conservation through such measures as the installation, in a proactive manner, of the state-of-the-art facilities for manure processing.

In addition to the role to address the concerns and needs for environmental conservation, the product of well-cured manure has been recognized for the merit of high quality, winning the Prize of Excellence in the Competitive Manure Show of Aomori organized by Livestock Industry Association of Aomori Prefecture, Inc. Hence, there is a high demand for the manure product from vegetable or fruit farmers in different zones of the Prefecture. The manure product is also contributing significantly to the development of regional agriculture as well as to the "Campaign for making the healthiest soil in Japan" promoted by the prefectural government of Aomori.

|

| |

|

|

|

|

(3) |

Challenge to livestock production based on resource recycling |

| |

|

The farm is trying to establish a livestock production system embodying the principle of resource recycling through relevant procedures such as "cattle manure processing→ soil making → cultivation of forage maize and rapeseed (rapeseed oil cake) → cattle rearing", which is to be verified by applying in-house processed manure to field plots of a former ranch of racehorses located in Shichinohe Town, the land of which was purchased in 2006.

The farm is in the process of acquiring equipment and materials that would allow it in the future to construct a more advanced system of livestock production based on resource recycling where agricultural machinery would make use of bio-diesel fuel to be processed from recycled rapeseed cooking oil from households or recycled edible oil from food-processing industry. The stance of the company in tackling the issue of resource recycling should be appreciated highly as an excellent model to be emulated by other actors.

|

|

|

(4) |

Collaboration and integration with local community |

| |

|

IAbove all, Mr. Kaneko attaches high value to collaboration and integration with local community, and is also committed to fostering successors of the sector, in participating in such programs as the acceptance of trainees of students from the Prefectural Farmers Academy.

In the former racehorse ranch which the company purchased and succeeded to in 2006, there are found eight valuable buildings of historical importance, registered as tangible cultural heritage, including the reportedly oldest surviving stable in Japan, in the style of traditional rural house of L-shaped plan, used for raising young colts, and a Matoh Kannondo (temple of horse-head deity of mercy), etc. In addition to having, on its own, taken charge of repair and maintenance of these cultural assets, and offering a recreation area to the townspeople, the company is committed to collaboration and integration with local community by organizing every year the annual festival and other festive events in which the people of neighboring community are invited to participate. Such a stance of the company is worthy of high praise.

Meanwhile, Mr. Kaneko holds an important public office, as vice-president of the Association of Fund for Price Stabilization of Formula Feed in Aomori Prefecture, deeply committed to smooth working of the Association faced with full of difficulties in the midst of steep rise of feed prices, thus contributing as well to the development of livestock production in the Prefecture.

The above describes generally the points for which the performance of Kaneko Farm has been appreciated. However, the essential fact is that Mr. Kaneko, while he is a farmer, is still committed to considering the three elements, "consumers, corporate person as producer, and contribution to society". In other words, he wishes to run his livestock farm by prioritizing the construction of relationship of trust, without forgetting the guiding principle for the vocation of merchant, namely, "Pursuit of happiness for three parties". His ideals are about to be thoroughly inherited by the successor who is looking out for the next generation of business, letting us anticipate to a great extent the sustainable development of the company in the future as well.

(Tooru Matsui, Chairperson of Judging Committee of Aomori Prefecture) |

| |

|

|

| |

|

Details of the reported case |

| |

(1)

|

Outline of the locality |

| |

|

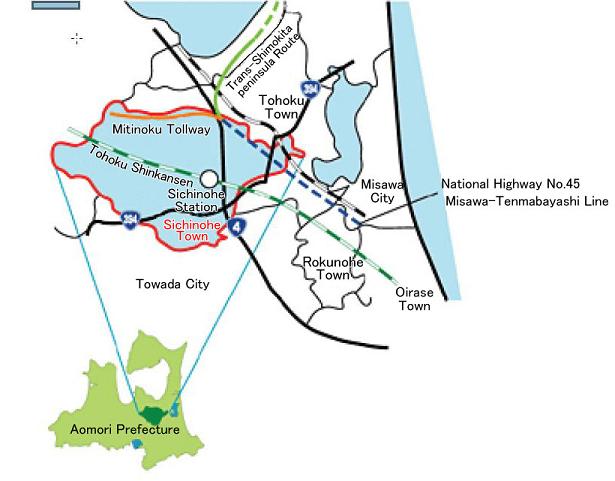

Shichinohe Town is located in the eastern part of Aomori Prefecture, constituting an inland administrative unit neighboring to Tohoku Town (former Kamikita Town) on the north and the east, Aomori City on the west, and Towada City on the south. The Town has been created since 2005 by amalgamation of 2 former administrative units: former Shichinohe Town and Tenmabayashi Village.

Trunk road network consists of the national route 4 traversing the town from south to north which is crossed by the national route 394 running from east to west, and a toll road called "Michinoku Highway" connecting with Aomori City. Other major municipal roads and prefectural roads constitute a network of radial pattern to connect with neighboring municipalities. The Town is, therefore, endowed with good conditions for communication over an extended area.

Besides, additional development projects are scheduled to be implemented, namely, the construction of a new railroad station of Tohoku Shinkansen near the town center and the improvement of the section between Misawa and Tenmabayashi of the ordinary national route 45 in the eastern part of the town. Such factors and geographical conditions make the Town a strategic communication hub in the region and the key area for comprehensive development of prefectural territory.

The principal industry of the town is agriculture. In terms of output value, the leading commodities are vegetables mainly composed of root crops such as Chinese yam and garlic (2.73 billion yens), that are followed by rice (1.76 billion yens), and livestock products (1.58 billion yens), in total amounting to 6.3 billion yens.

Regarding livestock production activities, although both the number of farms rearing animals and that of livestock heads had been on the decrease due to the impact of BSE in 2001 and the recent steep rise of feed prices, the trend has been stabilized in the past few years.

|

| Numbers of farms rearing principal species of animal and those of their heads |

| Year |

Dairy cattle |

Beef cattle |

Swine |

| No. farms |

Number of heads |

Number of heads |

Number of heads |

| Total No. heads |

Older than 2 years |

Younger than 2 |

No. farms |

Total No. heads |

Breeding |

No. farms |

Total No. heads |

Breeding |

| 1995 |

11 |

171 |

135 |

36 |

136 |

4,657 |

457 |

19 |

5,478 |

600 |

| 2000 |

7 |

146 |

106 |

40 |

106 |

5,055 |

428 |

13 |

5,775 |

553 |

| 2008 |

4 |

158 |

114 |

44 |

101 |

8,919 |

616 |

11 |

5,073 |

426 |

| 2009 |

3 |

157 |

120 |

37 |

102 |

8,850 |

636 |

11 |

4,244 |

439 |

| (2) Details of farming management and production |

| 1) Composition of labor force (as of July 2009) |

| Class |

Relationship with owner |

Age |

Number of days engaged in farming (day)

In animal sector

|

Section or task |

Note |

| Family member |

Owner |

58 |

300 |

300 |

Management of cattle for breeding and fattening |

General management |

| Wife |

57 |

300 |

300 |

do |

Assisting general management |

| Eldest son |

32 |

300 |

300 |

do |

General care of feeding |

| Eldest son’s wife |

29 |

300 |

300 |

do |

General administration task |

| Employee |

Permanent |

20s |

300 |

300 |

do |

5 persons |

30s |

300 |

300 |

do |

5 persons |

40s |

300 |

300 |

do |

5 persons |

50s plus |

300 |

300 |

do |

5 persons |

| 2) State of income |

| (1) Section components (as of the end of September 2009) |

| Section |

Usage |

Number of heads reared |

Remark on business operation |

| Livestock |

Fattening |

Dairy spp |

6,750 |

|

| Hybrid spp. |

1,500 |

|

| Japanese black cattle |

16 |

|

| Japanese shorthorn |

110 |

|

| Breeding |

Japanese black cattle |

4 |

|

| Japanese shorthorn |

50 |

|

| Total |

|

|

|

| (2) Breakdown of income by section (December 2007-November 2008) |

Section |

Product type |

Sales quantity |

Sales amount

(yen) |

Remark on business operation |

Livestock |

Sales of fattened cattle |

6,218 |

2,400,254,921 |

|

Sales of compost |

|

10,018,338 |

|

Total |

|

2,410,273,259 |

|

|

3) Land ownership and utilization (Unit: ha) |

| |

| Category |

|

Land area |

Note |

| |

Rented land |

Land used for animal production |

| Arable land |

40ha |

|

Converted paddy, forage crop plot |

| Grassland |

55ha |

|

Grazing land, meadow for forage harvesting |

| Forest |

10ha |

|

|

| 4) Production and utilization of on-farm grown forage (December 2007-November 2008) |

| Utilization mode |

Cropping system for growing forage |

Area (ha) |

Ownership |

Total yield

(t/ha)

|

Principal form of product (harvested forage) |

| Land area |

Harvested crop area |

| Harvesting |

Orchard grass, timothy |

50 |

50 |

Owned |

11 |

Roll |

| |

Forage maize (dent corn) |

26 |

26 |

Owned |

39 |

Roll, silage |

| 5) Outline of results of farming operation and technology elements |

| (1) Results of farming operation (December 2007-November 2008) |

Outline of farming operation |

Number of workers (livestock section, conversion by 2000 hrs/person/year) |

Family |

4.0 persons |

Employees |

20.0 persons |

Total area harvested for forage production |

176 ha |

Retrieval of rice straw |

120 ha |

Average number of heads of fattening cattle reared |

Beef species |

160 |

Hybrid species |

1,500 |

Dairy species |

6,750 |

Yearly number of heads of fattened cattle sold |

Beef species |

|

Hybrid species |

802 |

Dairy species |

5,416 |

Profitability |

Gross annual revenue |

54,938,601 yens |

Annual revenue per head of fattening cattle |

6,533 yens |

Income ratio |

2.3% |

Per head of fattening cattle |

Section revenue |

286,596 yens |

Revenue by sales of fattened cattle |

285,405 yens |

Sales cost |

307,392 yens |

Feeder stock cost |

110,830 yens |

Purchased feed cost |

155,662 yens |

Labor cost |

6,889 yens |

Depreciation cost |

7,712 yens |

Productivity |

Fattening (byspecies, fattening type) |

(Dairy steer), |

At the start of fattening |

Age in days |

210 days |

Weight |

300 kg |

Per head of fattened cattle |

Age in days at shipment |

570 days |

Live weight at shipment |

800 kg |

Average period of fattening |

365 days |

Daily gain (DG) of weight per head of fattened cattle sold |

1.39 kg |

Incident rate at destination |

1.0% |

Average sales price per head of beef cattle sold |

345,000 yens |

Sales price per kg of live weight of beef cattle sold (exclusive of tax) |

431 yens |

Sales price per kg of dressed carcass (exclusive of tax) |

750 yens |

Rate of meat with quality rated as equal to or higher than grade 3 |

16.0% |

Purchase price per head of feeder stock |

99,000 yens |

Purchase price per kg of live weight of feeder stock |

330 yens |

Net production cost per head of beef cattle shipped out |

414,144 yens |

Number of hours of labor expended per head of fattening cattle |

5.7 hours |

| (2) Outline of technology or other factors |

| Land classification |

Flatlandagricultural zone |

| Reared species |

Dairy, hybrid |

| Presence of successor |

Yes, 1951 |

| Rearing/milking |

Rearing system |

|

| Feed |

In-house blending of formula |

Yes |

| Adoption of TMR |

No |

| Use of byproducts of food processing |

No |

| Breeding/calf rearing |

Implementation of production by utilization of embryo transfer (ET) |

No |

| Implementation of production by F1 cattle |

No |

| Rearing by calf hatch |

No |

| Rate of in-house blended formula for cows |

No |

| Sales |

Availability of processing and sales section |

Yes. Original products (curry, jerky, honey, etc.) |

| Activities promoting "local products for local consumption |

Yes. Shipment to local supermarkets and roadside stations |

| Other activities |

Operation of fattening section |

Yes |

| Organization of collaborative and joint work |

No |

| Shared utilization of facilities and equipment |

No |

| Utilization of helping services |

No |

| Utilization of contractors |

No |

| Utilization of public grazing land for rearing heifers or steers |

Yes |

| 6)Possession status of principal facilities and machinery |

| Building and machinery |

Quantity |

Note |

| Building |

Animal shed |

29 |

Only in company’s own ranch |

| Compost barn |

4 |

Only in company’s own ranch |

| Machinery |

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| 7) Status of manure treatment and utilization |

(1) Details of treatment |

| Treatmentmode |

Mixed treatment |

| Method of treatment |

Fermentation by facilities for accelerated fermentation comprising vertical augers (2 buildings)

Fermentation by composters of closed vertical tank type

|

| Litter |

Rice straw, rice hull, sawdust, recycled compost, (microorganism material) |

| (2) Details of utilization |

| Destination |

Rate (%) |

Usage/final user or application |

Conditions |

Note |

| Sales |

60% |

Mainly farmers growing upland crops |

1,500~2,500 yens/t |

Delivery cost included |

| Exchange |

10% |

Mainly rice farmers |

None |

|

| Donation |

0% |

|

|

|

| On-farm consumption |

30% |

Forage plots, rapeseed plots |

|

|

| (3) Progress of the enterprise |

| 1) Evolution of operation and activities |

Year |

Commodity composition |

Number of heads reared |

Cultivated area of forage crops |

Details of operation and activities |

1971 |

Livestock production |

3 |

|

Started the operation of fattening beef cattle |

1972 |

do |

200 |

|

Increased number of heads mainly by rearing steers of dairy species |

1974 |

do |

0 |

|

Entire herd was disposed of on account of the impact of the first oil-shock. Worked as an employee in a trucking firm, but in the same year, restarted producing feeder stock of dairy breed as a side job of the employment in the firm. |

|

1975 |

do |

|

|

Relocation of farm. Construction of cattle sheds. Restarted full engagement in livestock farming. Started producing mainly feeder stock |

1978 |

do |

|

|

Restarted the combined operation of feeder stock breeding and fattening. |

1993 |

do |

1,500 |

|

Mimachi ranch established. Number of heads of reared stock reached 1,500. |

1998 |

do |

2,300 |

|

Started outsourcing a part of operation to other farms.Number of heads of reared stock reached 2,300. |

2001 |

do |

|

|

Eldest son started participating in farming. |

2002 |

do |

4,000 |

|

Number of heads of reared stock reached 4,000. |

2003 |

Compost production |

|

|

Installation of facilities for accelerated fermentation comprising vertical augers. |

2004 |

Compost production |

|

|

Installation of facilities for accelerated fermentation comprising vertical augers. |

2005 |

Livestock production |

|

|

Establishment of Kirita Ranch. Started processing primary products. |

2006 |

Compost production

Petting ranch |

|

|

Installation of composters of closed vertical tank type.

Establishment of "Kaneko Farm" at the former Morita Ranch. It was renamed "Happy Farm" and re-equipped to open a petting ranch. |

2007 |

Forage production

Livestock production |

130 |

35ha |

Started growing forage maize (dent corn) by using compost. Start rearing Japanese shorthorn cattle |

2008 |

Rapeseed production |

|

7ha |

Started growing rapeseed by using compost. Sales of original products (rapeseed oil, honey).

Second-eldest son started farming |

2009 |

Livestock production |

8,300 |

|

Number of heads of reared stock reached 8,300. A large-scale operation, running 5 farms under direct management and contracting 7 farms for outsourcing.

Committed to the realization of livestock production based on the principle of resource recycling |

|

| 2) Trend of production activities in the past 5 years |

| |

2004 |

2005 |

2006 |

2007 |

2008 |

| Number of workers in livestock section |

24 |

24 |

24 |

24 |

24 |

| Number of heads of reared animals |

4,493 |

5,258 |

6,018 |

6,043 |

6,396 |

| Quantity of sales, number of heads of shipped animals |

4,170 |

5,026 |

5,835 |

5,804 |

6,218 |

| Total sales amount of livestock section (1,000 yens) |

1,651,336 |

2,023,630 |

2,421,036 |

2,245,018 |

2,410,273 |

| Sales amount of principal products (1,000 yens) |

1,651,336 |

2,023,630 |

2,421,036 |

2,245,018 |

2,410,273 |

| |

(4) |

Details of business operation and production activities |

| |

1) |

Summary |

| |

|

Kaneko Farm, Co., Ltd., (represented by Mr. Haruo Kaneko, CEO, 58 years old) which owns farmland of vast area of about 130 ha in Shichinohe Town in the livestock production zone of Aomori Prefecture is the largest production farm in the Prefecture. In the spacious environment offering a magnificent view of Mt. Hakkoda, it raises a total of about 8,300 heads of beef cattle consisting of breeds of Holstein, hybrids, and Japanese shorthorn. It continues to produce home produced beef insisting on safety and reliability, based, since its beginning, on the fundamental principle that "the pursuit of profit is not the sole objective of business, but it has to offer the safe and reliable beef to consumers". Thus its activities are being developed to uphold such company credos as: "insistence on safety and reliability", "respect for environmental conservation

"challenge to livestock production based on the principle of resource recycling"; and "collaboration and integration with local community".

In the meantime, the company has experienced difficulties such as the first oil-shock and BSE but managed to overcome them and increased the number of heads of herd and the farmland area to arrive at the present operational scale.

Moreover, it is committed to not only raising cattle but also to the mission of offering without charge the place for people to learn about the importance of multiple functions of agriculture and the preciousness of life. It is also actively engaged in the conservation of cultural assets, and practices the farming that is closely linked with local community, contributing greatly to the regional development and presenting a model for others to emulate.

|

| |

|

|

| |

2) |

Insistence on safety and reliability |

| |

|

The signboard of Kaneko Farm is the company’s own brand breed of Holstein, "Ken-Iku-Gyu" (health-growth-cattle).Based on the concept that "Healthy and vigorous growth leads to safety and reliability", healthy feeder stock (6-7 months old) are introduced from contracted farms in Hokkaido. They are subsequently fattened on the formula feed of the company’s original formulation without any additives of antibiotics and on roughages composed of in-house grown forage maize (dent corn varieties) and rice straw hay from the Prefecture, to transform the cattle into safe, reliable and good beef produced in Japan.

The cattle of "Ken-Iku-Gyu" are sold to large meat processing companies that acknowledge the product’s taste, quality and safety, and are requesting the farm to boost the supply. The dressed meat is also distributed to cooperative stores within the Prefecture and enjoying popularity among consumers. The company has lately diversified its activities to the area of meat processing for such products as beef jerky and curry in a pouch that are sold over the Internet as well as in the local roadside station "Shichinohe".

|

| |

|

|

| |

3) |

Respect for environmental conservation |

| |

|

Based on the philosophy that "the prosperity of the company cannot be realized without understanding and cooperation of the people of local community", the company has been tackling the issue of environmental conservation by such measures as the installation in a proactive manner of the state-of-the-art facilities for manure processing.

The product of well-cured manure has been recognized for the merit of high quality for example by winning the Prize of Excellence in the Competitive Manure Show of Aomori organized by Livestock Industry Association of Aomori Prefecture, Inc. Moreover, since the company takes charge of delivery to final users, there is a high demand for the manure product from vegetable or fruit farmers in different zones of the Prefecture, and it is finding it difficult to meet all the demand. Quite a large number of orders come particularly from growers of apple and garlic, two commodities of which Aomori produces the largest quantity in the nation. In this way, the company is contributing significantly to the "Campaign for making the healthiest soil in Japan" promoted by the prefectural government of Aomori. |

| |

|

|

| |

4) |

Challenge to livestock production based on resource recycling |

| |

|

Prompted by the new acquisition in 2006 of parcels of agricultural land in the same town that used to be a ranch devoted to raising racehorses, the farm has launched an initiative to establish a livestock production system based on resource recycling, which is an advanced phase of activities developed from the preceding initiative for environmental conservation.

In more concrete terms, the farm started to grow forage maize (dent corn) on the land of former racehorse ranch by applying the in-house processed compost. The maize crop was processed into wrapped silage for feeding "Ken-Iku-Gyu" cattle to complete the material flow cycle of the system.

Furthermore, since 2008 the company has started to grow rapeseed that is one of industrial resource crops by applying only the compost of cattle manure and without agricultural chemicals on the parcel of about 7 ha in the same former racehorse ranch. The planted rapeseed crop has recreated the former cultural landscape of pretty mustard flowers and enabled the expression and sales of edible oil (product name "Ranch Rapeseed oil" and the production of single-flower honey derived from mustard flowers. Moreover, rapeseed oil cake is utilized as cattle feed, thus enabling the realization of the veritable livestock production system embodying the principle of resource recycling: cattle → soil → crops (forage maize, rapeseed) → cattle.

The farm intends to defy further challenge in which it retrieves rapeseed oildiscarded from households and food processing industry and convert it into BDF to be utilized for operating agricultural machinery. The farm envisages practicing in this way an environment-friendly livestock production system based on more sophisticated level of resource recycling principle through effective utilization of biomass resources. |

| |

|

|

| |

5) |

Production of Japanese shorthorn cattle |

| |

|

As an extended endeavor along the axis of insistence on safety and reliability as well as along that of challenge to the livestock production based on resource recycling principle, the farm started in 2007 to raise Japanese shorthorn cattle that are a local specialty of the northern Tohoku district. On a downward trend of the number of heads of this breed, the farm currently rears a herd of 160 heads, becoming the largest producer in the Prefecture as a private enterprise.

Kaneko Farm intends to increase the herd size in the future as well based on the belief, "The breed has strategic advantages such as high capacity for consumption of roughages, high tolerance for low quality feed, and capability for fattening even while it is reared on grazing. It is attractive to us particularly under the present harsh business environment including the steep rise of feed prices."

|

| |

|

|

| |

(5) |

Initiatives addressing the responsibility to the society |

| |

|

As previously described, since Mr. Kaneko is an incomer from another neighboring village, he considers that it is important to establish the environment promoting collaboration and integration with the inhabitants of local community so that he is able to maintain large-scale livestock farming on a sustainable basis, and therefore he takes particular care in ensuring the measures to conserve environment by making the utmost efforts in adequate processing of manure and the production and supply of high quality compost, and thus integrating his farming business organically into the overall structure of regional agriculture. Moreover, as also mentioned before, in the challenge to livestock production based on resource recycling principle, he recreated the pretty cultural landscape by planting rapeseed, providing pastoral solace to the local community, and has diversified the company activities by launching the processing of beef and direct sales of the products.

In addition to these initiatives, he is dedicated to the effort for fostering successors by accepting as trainees the students of Prefectural Farmers Academy. Moreover, Mr. Kaneko holds an important public office as vice-president of the Association of Fund for Price Stabilization of Formula Feed in Aomori Prefecture, and is deeply committed to smooth working of the Association faced with full of difficulties in the midst of steep rise of feed prices, trying to raise the rate of participation in the fund and to promote mutual conciliation among members, despite busy engagement with his own farm.

In another aspect of social contribution, as he purchased in 2006 the land of former racehorse ranch mentioned previously, he named it "Happy Farm" and opened a "Petting Ranch" where miniature horses, sheep, racehorses, etc are reared. He has constructed a public restroom there which goes well with surroundings, offering the entire ground to townspeople as a recreational area. Other area of activities into which Mr. Kaneko devotes his efforts also is to let the public understand better about the livestock production through learning about the importance of multiple functions of agriculture and the preciousness of life. For that purpose, he offers the facilities of the Ranch as a place for field trips of pupils of elementary schools and junior high schools in their classes of integrated study, or as that for opportunities of exchange with consumers.

Incidentally, in the former racehorse ranch there are found eight valuable buildings of historic importance, registered as tangible cultural assets, including the reportedly oldest surviving stable in Japan, in the style of traditional rural house of L-shaped plan and a Shinto shrine. In addition to having, on his own, taken charge of repair and maintenance of these cultural assets, Mr. Kaneko is actively engaged, by spending a large sum of private fund, in the effort for collaboration and integration with regional agriculture and local community by organizing every year as a devout person the annual shrine festival in which the people of neighboring community are invited to participate. |

| |

|

|

| |

|

|

| |

|

|

| |

(6) |

Policy and challenges for future development |

| |

|

As policy in general, in the future as well the entire personnel of the farm will make the utmost effort with flamboyant fervor and their whole heart like the gigantic lantern of "Aomori Nebuta" festival, in the continuous pursuit of "Safety", "Reliability" and "High quality". Besides, the company carries out the activities of production by prioritizing the food safety over the efficiency of production, since it is charged with the task of production of food that is essential for human life. Profitability is not the sole objective. In this context, it will be the key policy of the company to try to communicate with consumers adequately, by disclosing all the relevant information concerning production.

The company will continue to maintain in the best condition the "Happy Farm" that has been established as a recreational area for townspeople and historical buildings, in order to inherit faithfully the traditional culture of the local community. The company intends to strive for the collaboration and integration with the local community by recognizing that the farm is able to survive only through the existence among the people there. As problems needing solution, there are worries caused by external factors such as the steep rise of feed prices and falls of the wholesale price of beef due to economic depression. However, such factors cannot be controlled by the company itself, and the only possible way to cope with them is to strive as best as it can for solutions that it is able to find by itself step by step. The company will sustain, as heretofore, its policy for running business, "Chisoku-Anbun" (virtue of satisfaction with what one actually has), i.e., "action based on down-to-earth reality".

In conclusion, the company will pursue the way of livestock production business which values the construction of mutual confidence as the most important matter above anything else, without forgetting, despite the position as a farmer, the spirit of merchant that is "Happiness for three parties", caring about the well-being of three elements, namely, consumers, producers including the company, and the contribution to the society.

|

| |

|

|

| |

|

|

Beef of original brand "Ken-Iku-Gyu", insisting on safety and reliability |

|

Compost of high quality commands a great demand from local crop growing farmers |

Growing rapeseed utilizing compost but without chemicals |

|

Original product of beef jerky |

Efforts toward self-sufficiency in feedstuff in pursuit of safe feeding |

|

Local children come to visit the petting ranch, "Happy Farm" |

Commitment to conservation of local cultural assets, caring about the integration with the local community |

|

Rearing of Japanese shorthorn cattle with the high capacity for consumption of roughages |

|

|

|

|